- Products

- Automotive

- Avionics

COTS Module

- Agilex 7 SmartNIC Card

- Zynq RFSoC ADC DAC PCIe Card

- ZU7/ZU5/ZU4 PCIe SmartNIC Card

- ZU19/17/11 PCIe SmartNIC Card

- PCIe Switch Module

- PCIe to SD 3.0 M.2 Module

- Kintex-7 PCIe Card

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Virtex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- Zynq ZU19/17/11 3U VPX

- Kintex-7 3U VPX Card

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x16 FMC+ Module

- PCIe Gen3 x8 FMC Module

- Quad QSFP28 FMC+ Module

- FMC Add-On Cards

- IP Cores

- ODM Solutions

- Custom Design

- Company

Get a Quote

Please fill in the form and we will get back to you soon!

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Get in Touch

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Thank you for subscribing to our newsletter!

The Need for Thermal Management in Embedded Boards and Solutions

Increased edge processing, Performance enhancements, and miniaturization of embedded platforms and solutions have led to an increase in power consumption and heat generation leading to the creation of thermal hotspots. As a result of thermal stress, there can be a significant level performance degradation of the embedded system and even cause the entire system to fail. In addition, long-term exposure to excessive heat reduces the lifespan of electronic components.

Understanding thermal management techniques plays a significant role in maintaining a device in optimum operating condition. Advancements in the electronics industry have led to the need for innovative thermal management technologies to enhance system reliability and performance. According to Market Research Future, the global thermal management market is expected to reach USD 20.3 billion by 2030, growing at an 8 percent CAGR between 2022 and 2030.

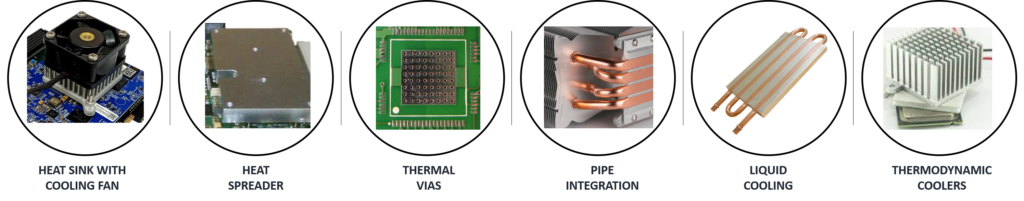

Common heat dissipation techniques in embedded solutions

Heat dissipation techniques are more crucial than ever, with systems becoming smaller and more powerful. A designer can use several methods to remove heat from the components and PCB and the common mechanisms include:

- Hear Sinks and cooling fans

A large-surfaced thermally conductive metallic part acts as a passive heat exchanger, dissipating heat to the surrounding air via conduction, with the possibility to add cooling fans to heat sinks to aid in the removal of heat faster and more effectively.

- Heat pipes integration

Heat pipes are cooling devices used in high-temperature applications. A typical heat pipe consists of a fluid that absorbs heat, vaporizes, and travels along the pipe. At the condenser end, the vapor turns back to liquid form, and the cycle repeats.

- Heat spreaders

A heat spreader has a large flat surface on top that is usually pressed directly against another large flat surface. It allows heat transfer from a smaller spreader to a larger metal surface. Heat spreaders are ideal for devices that withstand extreme shocks and vibrations or inside sealed containers. Heat spreaders are perfect for devices subjected to shock and vibration or systems that must remain sealed within an enclosure.

- Thermodynamic coolers (TECs)

A thermodynamic cooler is ideal for systems where the component temperature has to be kept constant. Processors with high power dissipation use a combination of TECs, air cooling, and liquid cooling to extend the conventional air-cooling limits.

- Thermal vias

Thermal via arrays are incorporated over the copper-filled areas and placed close to the power source. In this method, the heat flows from components to the copper area, dissipating through the air from the vias. Thermal via arrays are often used in power management modules and components with thermal pads.

- Liquid cooling systems

Because liquids can transfer heat four times faster than air, they enable higher thermal performance in a smaller solution. A liquid cooling system includes a cold plate or cooled enclosure to interface with the heat source or device, a pump or a compressor to circulate the liquid through the system, and a heat exchanger to absorb the heat from the device and dissipate it safely.

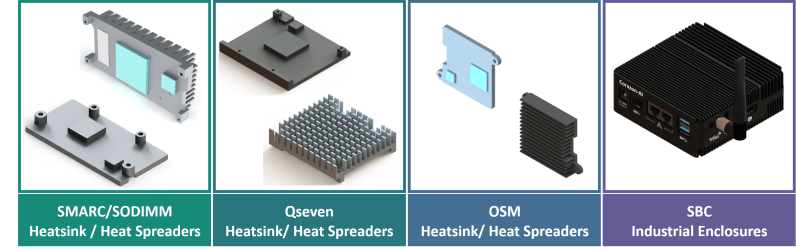

Thermal Solutions from iWave

With an expert team of mechanical engineers, iWave designs heat sinks, fan sinks, and enclosures that fit the specific thermal characteristics of the product. Thermal simulation software is used to help engineers determine the most appropriate cooling method for their circuits and understand the thermal parameters associated with them to improve overall product reliability. It assists the designer in determining the following aspects,

- Heat flow pattern

- Heat sink design

- Cooling methods for active devices

iWave uses Ansys Icepak cooling simulation software to identify thermal hotspots and to provide the best recovery solution. Based on the total surface area identified in the design software, theoretical heat dissipation values are calculated, followed by testing the board in Ansys Icepak software to understand how the product behaves at various operating temperatures and to collect the junction temperature data. Finally, the best heat dissipation technique is designed to suit the product.

iWave offers thermal solutions for all form factors, including OSM, SMARC, Qseven, and SODIMM. These thermal solutions utilize aluminum alloy AL6063 due to their excellent material properties. Aluminum, in particular, is an excellent conductor, non-toxic, recyclable, and has excellent durability making it an ideal choice for transferring heat from components. Through in-house thermal solutions, a product designer can reduce the cost of implementation by eliminating engineering delays, field failures, and product iterations.

Reducing the amount of heat dissipated by the device is the easiest way to improve efficiency. Despite this, you can always increase the reliability of your design by reducing the heat dissipated from the board, irrespective of the success you achieve with cooling methods.

Find out more about iWave thermal solutions expertise by contacting us.

If you have any questions, drop us an email at mktg@iwave-global.com.

iWave is an embedded systems engineering and solutions company, designing solutions for the Industrial, Medical, Automotive and Avionics vertical markets, and building on our core competency of embedded expertise since 1999. Read More…

Newsletter

Copyright © 2022 iWave Systems Technologies Pvt. Ltd.