- Products

- Automotive

- Avionics

COTS Module

- Agilex 7 SmartNIC Card

- Zynq RFSoC ADC DAC PCIe Card

- ZU7/ZU5/ZU4 PCIe SmartNIC Card

- ZU19/17/11 PCIe SmartNIC Card

- PCIe Switch Module

- PCIe to SD 3.0 M.2 Module

- Kintex-7 PCIe Card

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Virtex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- Zynq ZU19/17/11 3U VPX

- Kintex-7 3U VPX Card

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x16 FMC+ Module

- PCIe Gen3 x8 FMC Module

- Quad QSFP28 FMC+ Module

- FMC Add-On Cards

- IP Cores

- ODM Solutions

- Custom Design

- Company

Get a Quote

Please fill in the form and we will get back to you soon!

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Get in Touch

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Thank you for subscribing to our newsletter!

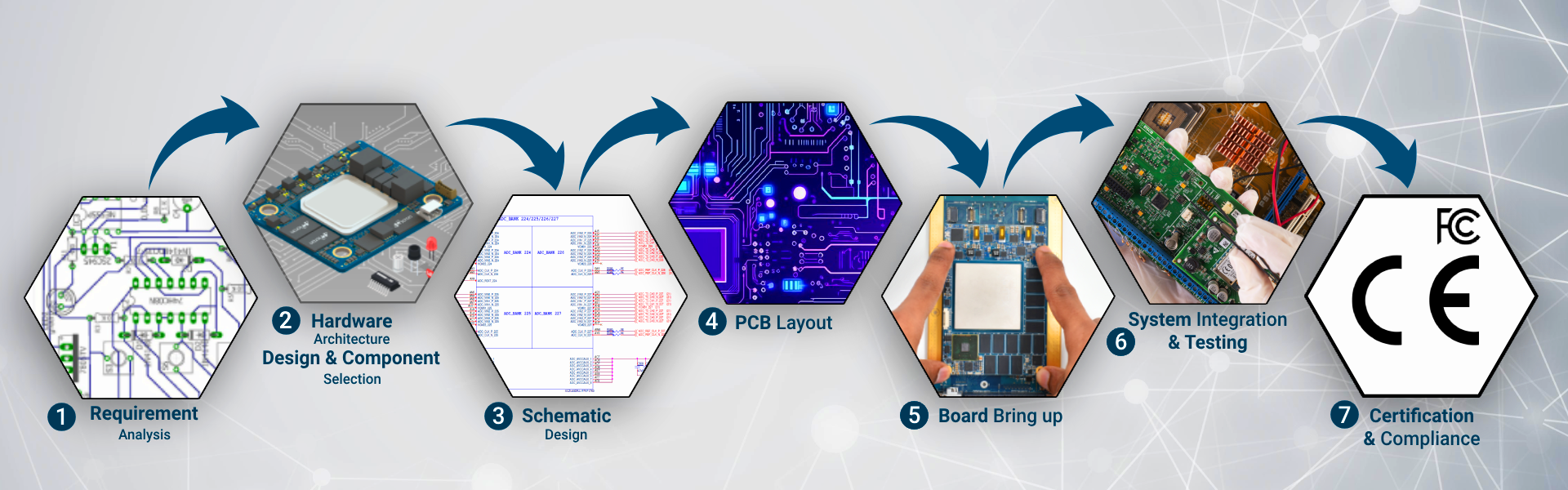

Product Design Process

Product Design Process

Our Product design process is meticulously crafted to transform your vision into reality, ensuring innovation, quality, and customer satisfaction at every step. Here’s how we bring ideas to life through our comprehensive design process.

Our approach to product design is rooted in collaboration and innovation. We believe in understanding your specific needs and objectives before diving into the creative process. This ensures that every design decision is purposeful and aligned with your goals.

Product design and Manufacturing Process

1. Requirement Analysis

Requirement Analysis is the process of generating, developing, and refining ideas for new products, product improvements, or product extensions. It’s a crucial phase in the product development cycle as it lays the foundation for creating innovative and successful products. Below are the design capabilities,

iWave provides free Engineering Services and Estimates

- Engineers to determine what the customer needs

- Non-recurring engineering (NRE) estimate: An estimate for the cost of researching, developing, designing, and testing your custom product.

- Ongoing manufacturing estimate: An estimate detailing the production costs for manufacturing your customized product.

- Ensuring Budget Alignment: We will provide you with the estimates to ensure that our budgets are in sync. Our goal is to keep you informed and involved throughout the project.

- Moving Forward: If the budgets align, we proceed to Step 3. If not, we collaborate to reach an agreement on a revised estimate.

Generate Formal Hardware Specification & Statement of Works

- Formal Hardware Preliminary Specification: This document presents the initial technical specifications of the custom product.

- Statement of Work: This outlines the project steps based on the specifications, including the project schedule.

- Commitment to Transparency: We believe in transparency throughout the process. The preliminary specification, statement of work, and schedule will be shared with the customer for step-by-step agreement. This ensures that the customer receives precisely what they request.

2. Hardware Design & Component Selection

Our expert team provides end-to-end hardware design services, from conceptualization to production, ensuring your project meets all technical and budgetary requirements. We specialize in selecting the optimal components to enhance performance, reliability, and scalability, leveraging the latest advancements in technology. Our meticulous process involves thorough analysis, simulation, and testing to ensure seamless integration and functionality. Whether you’re developing consumer electronics, industrial machinery, or IoT devices, our tailored solutions and strategic component sourcing guarantee excellence and innovation in every design. Explore our services to discover how we can bring your hardware vision to life with precision and expertise.

3. Schematic Design

Schematic design is the foundational stage in the electronic design process, where the conceptual framework of an electronic system is transformed into a detailed diagram. This diagram, known as a schematic, serves as a comprehensive blueprint that maps out the electrical connections and components within a circuit. It is an essential step that ensures the proper functioning and integration of various electronic elements before moving on to the physical implementation.

4. PCB Layout

At iWave, we’re keenly aware of the key role PCB layout plays in electronic device design. Our meticulous approach ensures optimal component placement and efficient electrical connections, effectively minimizing noise, enhancing signal integrity, and guaranteeing reliable performance. Leveraging advanced software tools, we meticulously craft precise and manufacturable layouts that adhere to industry standards. Whether it’s a simple or complex board, a well-designed PCB layout is indispensable for the success and longevity of electronic products.

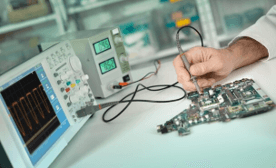

5. Board Bring up

Board Bring-Up stage is a critical phase in hardware development where the newly designed circuit board is powers on and tested for the first time. We conduct detailed checks to ensure all components are correctly installed and functioning, including power-up tests, signal integrity verification, firmware loading, and debugging. This critical phase is essential for identifying and resolving any issues early, ensuring your project moves smoothly towards production with confidence in its reliability and performance.

6. System Integration & Testing

we specialize in seamlessly combining various system components and rigorously testing them to ensure flawless performance. Our expert team handles every aspect, from software and hardware integration to comprehensive performance and compatibility testing. By identifying and resolving potential issues early, we ensure your system operates smoothly and reliably. Trust us to manage the complexities of integration and testing, ensuring your project is ready for successful deployment.

7. Engineering Samples

Our engineering samples reflect the design, functionality, and quality of the final products, allowing you to evaluate and test them in real-world applications. Essential for validating designs, conducting performance tests, and gathering feedback before full-scale production, these samples provide the precision and reliability you need. Whether assessing new components, developing custom solutions, or conducting feasibility studies, our prototypes exemplify our commitment to excellence and innovation, ensuring your projects move forward with confidence.

Related products

Download

Please fill in the form below to download the document.

Thanks for filling in the download form.

Request Document

Please fill in the form below and we will get back to you soon!

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

iWave is an embedded systems engineering and solutions company, designing solutions for the Industrial, Medical, Automotive and Avionics vertical markets, and building on our core competency of embedded expertise since 1999. Read More…

Newsletter

Copyright © 2022 iWave Systems Technologies Pvt. Ltd.