Telematics Enabling Smart Monitoring and Fault Diagnostics in Engines

Diesel Engines are critical system components in a majority of applications ranging from industries, mining, healthcare, construction, data centres, banks and utilities. Fault occurrence and a down time in the engines can lead to a monetary impact. Hence, there has been an increased adoption of smart monitoring solution for diesel engines.

Why is Telematics required for engines?

As the monitoring and maintenance of diesel engines have always been manual and onsite, it results in heavy loss for industries, rental agencies, and customers due to lack of relevant data. Telematics for diesel engines ensures uninterrupted operation.

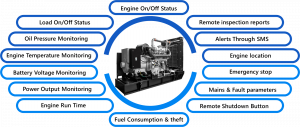

Telematics provides visibility on various parameters such as engine power, fuel consumption, location and hours of usage. Insights on these parameters can help optimize maintenance schedule and preventing generator service outage. Telematic can also support further analysis through software that provide predictive analytics, user alerts, intelligent dispatching, and many other valuable features. With the help of these powerful metrics, users and businesses can create significant savings, return on investment (ROI), improve customer service and across operations.

Diagnostics data for engines

Telematics device pulls the data from the onboard diagnostics system to provide valuable information on machine health, performance, and status. Diagnostic information includes fuel consumption, engine run time and the power status.

Typically, the results of this data reach the user in easy-to-read software systems, many of which can be accessed from any device. In addition to sending data online, smart telematics solution sends reports via SMS-notifications on detected events. Some of the challenges that telematics solutions can solve consist of scheduling maintenance and stolen equipment recovery.

Few reasons why a Smart Monitoring Solution is necessary for engine manufactures:

- Streamline performance by continuously monitoring vital parameters across the deployment sites

- Improve decision by accurate detailed insights and real-time analytics of diesel engine performance

- Enhance customers satisfaction by proactively addressing issues before they become problems

- User defined SMS alerts for engine faults and misuse

- Classification of information (region wise / model wise / dealer wise)

- Higher profit by tracking the fuel consumption, fuel theft, unauthorized usage and also reduces operational costs as there is no manual dependency

Importance of rugged telematics hardware

Diesel engines works in tough conditions and demanding environments. To track engines effectively, user need a telematics solution that is built to operate where engines are located and work in the same difficult conditions.

To connect to the engines, the telematics hardware is integrated with connectivity options such as CAN, RS232 and RS485. Based on the installation area, there is also different wireless connectivity options to be considered such as LTE Cat-4, LTE Cat-M1 and Wi-Fi.

A ruggedized telematics device is designed for harsh outdoor environments common in industrial, heavy-duty and utilities applications. The telematics device features a rugged exterior enclosure that allows for installation outside, withstand shaking and shocking. Device is designed according to the international standard IP67 strengthened to withstand intrusion of solids, dust, accidental contact, cold and water.

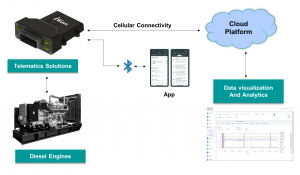

iWave Hardware for Diesel Engines monitoring

Our innovative portfolio of telematics solutions and protocol stacks are designed to work with any engines to remotely monitor vital aspects and provide real-time information on key parameters. Rugged Telematics Device can be installed along with the intelligent sensors on the diesel engines, that monitor various parameters such as fuel consumption, diesel engines run hours, fuel refills, health, battery voltage, coolant level, pressure, temperature, and energy for a seamless operation.

The sensors communicate with our gateway device and then transmits these readings to server or cloud over the internet. The sensors monitoring the diesel engines works on 4G wireless technology. Through user interactive web and mobile applications, engine parameters can be viewed in real time and can create reports anywhere and anytime. A remote monitoring platform allows users to monitor the equipment 24×7 across multiple locations addressing the challenges.

The SAE J1939 protocol stack is used to collect the parameters from diesel engines, we have developed the stack based on the ANSI C standard supporting all the specifications of the SAE J1939 protocol needed for collecting data from diesel engines. The stack works with an extended 29-bit CAN identifier with all the standard baud rates (100kbps, 125kbps, 250kbps, 500kbps, and 1000kbps) supported.

The telematics gateway device interfaced with diesel engines provide the following benefits:

- Monitoring a range of important parameters related to engines

- Option to add additional sensors

- Secured data storage and analytics capabilities

- Preventing fuel thefts

- Monitoring the machine run time

- Record fuel consumption and draining

- Emergency fuel balance

We offer a fully scalable solution to monitor and diagnose entire engine from anywhere, anytime assuring user peace of mind. Our predictive technology makes sure that your generators are in good and healthy condition to function uninterruptedly in an event of an emergency and prevent fuel thefts and generator breakdown.

To get in touch with iWave for enquiries and any further information, you can reach us at mktg@iwavesystems.com

Learn more at:

Keep Reading

|  |  |

| The importance of telematics in Electric Vehicles | Protocol stacks to speed-up industrial and automotive product development | Telematics Gateway with J1939 Data Logging for Off-Road Vehicles |