OSM Solderable System on Module and its Advantages

The new OSM (Open Standard Module) standard ratified by SGET allows the module to be directly soldered onto the carrier card as a solder-on-module, eliminating the need for an edge or board-to-board connector. The OSM specification aims to standardize the footprint and interface set of low-power application processors based on MCU32, ARM, and x86 architectures across different manufacturers, sockets, and architectures.

Distinct advantages of OSM System on Modules include,

- PCB Solderable Module:

Although the industry has long used push connector modules, Solderable System on Modules are quickly gaining traction. Direct soldering of the SoM onto the carrier board ensures high levels of robustness, enables automated assembly by pick and place machines, and allows unique mapping of the module to the carrier card. The corresponding communication interfaces are provided via the contact pads available below the module.

- Robust (Shock & Vibration resistant):

OSM-based System on Modules offers an extra level of ruggedness to the products that are susceptible to vibrations and require a compact form factor. The combination of LGA design and surface mount technology (SMT) makes the system robust enough to withstand high vibrations. Furthermore, it reduces production costs in series production.

- Compact form factor:

Using LGA technology makes it possible to implement significantly more interfaces on a smaller footprint, which is ground-breaking in terms of miniaturization and increasing requirements complexity. The provision for the smallest pin-to-area ratio allows the designer to access the maximum number of pinouts.

OSM standard and its variants

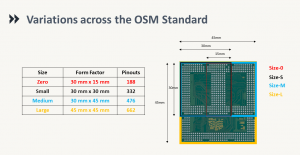

Depending on the LGA contacts available on the module, the OSM presents four different sizes ranging from size zero, small, medium, and large.

The pinouts are designed in such a way that the carrier board can accommodate all the sizes onto a single slot, making them exceptionally future-proof and versatile.

When to go for what form factor

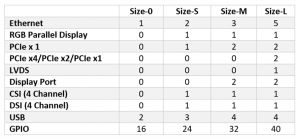

The type and design of the interfaces vary depending on the size of the OSM modules.

Video interfaces for up to 1x RGB and 4-channel DSI are available on modules starting with Size-S. All modules from Size-S and up also include a 4-channel camera serial interface (CSI).

To support large panel displays, Size-L supports a 1x LVDS graphics interface. Furthermore, the Size-L supports up to 10 PCIe lanes for quick connection of peripherals; Size-M offers 2x PCIe x1, and Size-S 1x PCIe x1.

Size-L has up to 5 Ethernet ports for system-to-system communication, which can be very useful in networking applications. OSM has been very generous in providing GPIO contacts up to 40 in size-L.

In addition, all modules have a dedicated communication area with 18 pins for antenna signals to support various wireless technologies. Up to 19 pins are further available for manufacturer-specific signals.

A quick comparison between SMARC, Qseven, and OSM standard

Solderable LGA mini modules with the new OSM specification are significantly smaller than those with the previous SGET specification. The largest OSM module, measuring 45x45mm, is 28% smaller than the Qseven (40x70mm) and 51% smaller than SMARC (82x50mm).

Size-0 (zero) has the smallest footprint with 188 LGA pins on 30x15mm. OSM Size-S (small) measures 30x30mm with 332 pins, OSM Size-M (Medium) offers 476 pins on 30x45mm, and Size-L (large) measures 45x45mm with 662 LGA pins. In comparison, SMARC specifies 314 pins while Qseven specifies 230.

iWave has built an extensive portfolio in the OSM standards – i.MX 8M Plus, i.MX 8XLite, and i.MX 93 powered system on modules.

For more information, please contact us at mktg@iwavesystems.com or visit our website at www.iwavesystems.com.

Keep Reading

|  |  |

| i.MX 8M Plus OSM System on Module | i.MX 8XLite OSM System on Module | i.MX 8XLite powered V2X Connectivity Hub |