- Products

- Automotive

- Avionics

COTS Module

- Agilex 7 SmartNIC Card

- Zynq RFSoC ADC DAC PCIe Card

- ZU7/ZU5/ZU4 PCIe SmartNIC Card

- ZU19/17/11 PCIe SmartNIC Card

- PCIe Switch Module

- PCIe to SD 3.0 M.2 Module

- Kintex-7 PCIe Card

- Zynq ZU7/ZU5/ZU4 3U-VPX

- Virtex UltraScale+ 3U VPX

- Kintex UltraScale+ 3U VPX

- Zynq ZU19/17/11 3U VPX

- Kintex-7 3U VPX Card

- VITA 57.4 FMC+ Loopback Test Module

- VITA 57.1 FMC Loopback Test Module

- PCIe Gen4 x8 FMC Module

- PCIe Gen4 x16 FMC+ Module

- PCIe Gen3 x8 FMC Module

- Quad QSFP28 FMC+ Module

- FMC Add-On Cards

- IP Cores

- ODM Solutions

- Custom Design

- Company

Get a Quote

Please fill in the form and we will get back to you soon!

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Get in Touch

We appreciate you contacting iWave.

Our representative will get in touch with you soon!

Thank you for subscribing to our newsletter!

i.MX 8QuadMax SoM for Digital X-Ray Machines

Since the advent of digital X-ray machines, the way radiology departments operate has changed. These modern X-ray machines produce digital radiographic images instantly on a computer. Digital X-ray machines consist of flat-panel detectors, also called X-ray sensitive plates, which capture data while examining the objects and transfer the information directly to the computer without an intermediate cassette.

Compared to traditional X-ray systems, digital X-ray machines improve diagnostic image quality while reducing the patient’s exposure to radiation and eliminating chemical processing costs.

A leading supplier of medical diagnostic equipment was looking for an off-the-shelf System on Module with universal applicability demonstrated by a diverse peripheral set such as PCIe interface, Gigabit Ethernet, USB 3.0, etc., that allows easy integration with the FPGAs in their design. The hardware design had to overcome multi-disciplinary technological challenges, including designing a flexible and scalable platform that could support multiple sensor configurations and accelerate development time.

Key challenges

- Scalable platform with extensive peripheral support

- Ability to support multiple sensor configurations

- Supports multiple high-speed interfaces

- Accurately convert high-speed signals

- Faster boot time

- Improve product development time and effort

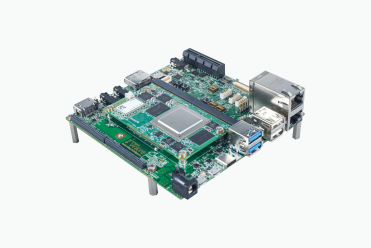

Considering the above challenges and requirements, iWave proposed the System on Module based on the NXP i.MX 8QuadMax SMARC.

The team decided to use the i.MX 8QM SMARC System on Module for its scalability and performance and easily integrates with the FPGAs used in their design. The development board and reference design provided by iWave helped the team to jumpstart the project while reducing the design risk.

Flat-panel displays are composed of multiple sensors that work together to create a high-resolution image. Hence, system designers had to integrate extremely sensitive sensors with high-speed digital processing capabilities into a low-profile enclosure. The first step in image acquisition is to capture raw data from sensors. Readout rates up to 10Gbps were required depending on the sensor resolution and desired frame rate.

The development board supports dual PCIe interfaces for transferring raw data from the sensors to the FPGAs. The FPGAs accept the raw data, decode the incoming streams, aggregate them, and perform data serialization. Finally, all of the pixels in the image are reordered, and the FPGAs perform additional image processing operations to improve the image’s quality.

The system uses AI tools to automate some of the technologists’ manual tasks and assists reading radiologists with new decision support resources. Furthermore, they help prioritize critical cases to detect subtle or complex patterns within X-Ray images, improving efficiency, quality, and clinical accuracy.

System designers can tailor the i.MX 8QuadMax development board to suit medical device manufacturer requirements and satisfy system integration parameters. The module offers extensive high-speed interfaces, such as Gigabit Ethernet, PCIe Gen3, USB3.0, SATA3.0, and multiple GPIO interfaces, enabling broad system connectivity and simplifying industrial qualification.

The SoM plus carrier card approach provides a complete production-ready computing platform with multiple connectivity options such as display, wired & wireless connectivity, GPIO, and other subsystems on a single platform that optimizes a significant amount of product development time with reduced cost.

The client also required a SoM partner committed to product longevity. With an eye for the demand for the supply of System on Modules in years to come, the iWave ensures a strong supply chain for the customers with a minimum of 10 years of product longevity. Hence, product designers can focus on their design without worrying about the product going absolute.

More information on i.MX products can be found here.

If you have any queries, drop us an email at mktg@iwavesystems.com.

Keep reading

iWave is an embedded systems engineering and solutions company, designing solutions for the Industrial, Medical, Automotive and Avionics vertical markets, and building on our core competency of embedded expertise since 1999. Read More…

Newsletter

Copyright © 2022 iWave Systems Technologies Pvt. Ltd.